- 1. Higher Filtration Capability

- The filtration capability of conventional cotton drain filters is limited to 1μm: however, the capability of hollow fiber membrane elements is at least ten times finer with porosities of 0.1 μm (and even much less).

- 2. Highly Thermal Resistant (Up to 99℃)

- Hollow fiber membrane elements are used in industrial applications where high thermal resistance is required. Thermal resistant membranes used with a SUS housing can remove impurities from hot water up to 99℃ (but not directly from steam drainage).

- 3. Automated Backwashing

- By conducting periodic automated backwashes or chemical acid washes, hollow fiber membrane elements can be used for extended periods of time while maintaining high filtration precision.

- 4. Small Space Requirement

Hollow fiber elements can provide a large membrane filtration area in a very compact configuration, thus the complete treatment system requires a relatively small footprint.

Hollow Fiber Membrane Element

Hollow Fiber Membrane Element

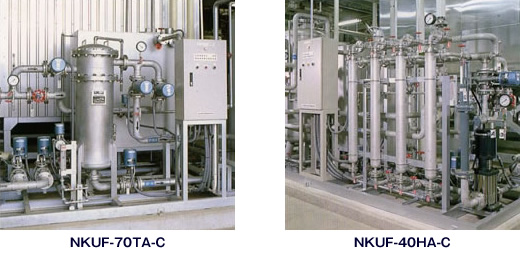

The NKUF-type drain filter process removes metal oxides such as iron from steam drainage using microfiltration (UF) membranes, thus the drainage can be effectively reused as feed water.

Recycling and reusing drainage has several advantages for saving energy and resources including reducing boiler fuel demand, saving feed water and cutting treatment cost. However, if drainage is reused without proper treatment, corrosion will occur due to metal oxides in the water, which will result in an increased incidence of boiler blowout, thus inhibiting stable operation.

The equipment mounted on the frame consists of pumps (for liquids), membrane filtration modules, pipe valves and measurement gauges.

The system can be used immediately after installation, which involves making plumbing connections and wiring for the primary power supply.